Propeller BlocklyProp Block Reference

-

Control

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

Operators

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

Numbers

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

Strings

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

Values

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

Variables

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

Functions

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

Pin states

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

Communicate

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

Serial LCD

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

OLED

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

Terminal

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

Protocols

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

XBee

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

Sensor

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

HMC5883L

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

2-Axis Joystick

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

Memsic 2-axis

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

MMA7455

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

Ping))) Distance

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

PIR

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

RFID

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

Sony Remote

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

Sound Impact Sensor

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

ColorPal

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

Memory

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

Analog / Pulses

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

Audio

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

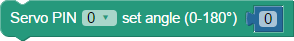

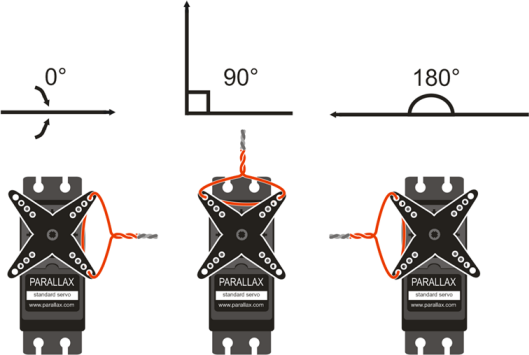

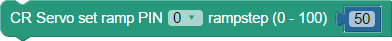

Servo

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

RC time

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

Voltage

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

Pulse in / out

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

PWM

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

Robot

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

LSM9DS1 9-axis IMU

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

RGB LEDs

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

WX WiFi

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

Simple WX

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

Advanced WX

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

Arrays

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

Fingerprint Scanner

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

IR Remote Wiring & Example Code

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

PING))) Wiring & Example Code

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

Memsic 2125 Wiring & Example Code

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

Joystick Wiring & Example Code

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

PIR Wiring & Example Code

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

ColorPal Wiring & Code Example

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate

- Serial LCD

- OLED

- Terminal

- Protocols

- XBee

- Sensor

- HMC5883L

- 2-Axis Joystick

- Memsic 2-axis

- MMA7455

- Ping))) Distance

- PIR

- RFID

- Sony Remote

- Sound Impact Sensor

- ColorPal

- Memory

- Analog / Pulses

- Audio

- Servo

- RC time

- Voltage

- Pulse in / out

- PWM

- Robot

- LSM9DS1 9-axis IMU

- RGB LEDs

- WX WiFi

- Simple WX

- Advanced WX

- Arrays

- Fingerprint Scanner

- IR Remote Wiring & Example Code

- PING))) Wiring & Example Code

- Memsic 2125 Wiring & Example Code

- Joystick Wiring & Example Code

- PIR Wiring & Example Code

- ColorPal Wiring & Code Example

- GPS

- Sound Impact Wiring & Example Code

- RFID Wiring & Example Code

- Fingerprint Scanner Wiring & Example Code

- GPS Wiring & Example Code

- 4 x 4 Keypad

- About Naming Things

- 4×4 Keypad Wiring & Example Code

- Graph

- System

- About Multicore

- About BlocklyProp Updates

- Temp & Humidity

- Temperature & Humidity Sensor Wiring & Example Code

- Badge Display

- Badge Buttons

- Badge LEDs

- Badge Lock

- Air Quality BME680

- ePaper

- LIS3DH Accelerometer

- About Board Types

- BlocklyProp Bulk Project Download

-

GPS

- Control

- Operators

- Numbers

- Strings

- Values

- Variables

- Functions

- Pin states

- Communicate